Hybrid PCB Built on 8mil (0.203mm) RO4003C and 0.2mm FR-4 Multilayer High Frequency PCB Combining RO4003C and FR-4

(PCBs are custom-made products, the picture and parameters shown are just for reference)

Introduction

Hello Everyone,

Warm greetings!

Today, we will discuss a 4-layer hybrid PCB that combines 8mil (0.203mm) RO4003C and FR-4, designed specifically for attenuator applications. This PCB has a thickness of 1.1 mm and features a blue solder mask with immersion silver plating on the pads, along with 1oz copper on each layer. Overall, it represents a straightforward multilayer PCB with a hybrid structure. These boards are manufactured according to IPC 6012 Class 2 standards using the provided Gerber data. Each board undergoes 100% electrical testing prior to delivery, with 25 boards packed for shipment.

.jpg)

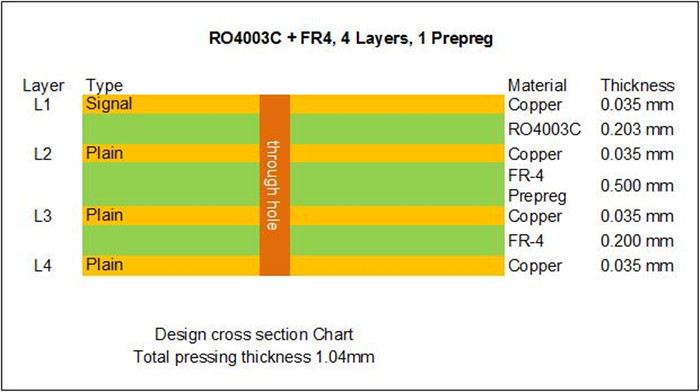

Let’s look the stack-up:

The stack-up consists of layers from 1 to 2 made of the fixed thickness RO4003C core (8mil), which is crucial for maintaining the electrical length of RF lines on the circuit board. The remaining layers utilize FR-4 materials, and all boards feature through holes.

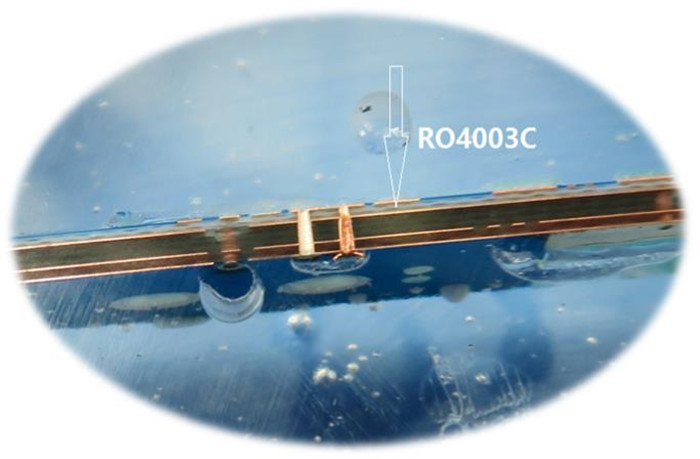

Below is a micro-section drawing:

Features and Benefits

1.Stable Dielectric Constant: RO4003C provides a consistent dielectric constant across a wide frequency range, making it an ideal substrate for broadband applications.

2.Improved Signal Integrity: This hybrid stack-up enhances signal integrity compared to traditional all-FR-4 constructions.

3.Certifications: Our manufacturing processes are ISO9001, ISO14001, IATF16949, ISO13485, and UL certified.

4.Comprehensive Testing: We conduct thermal stress, reliability, insulation resistance, ionic contamination, and AOI tests to ensure quality.

5.No Minimum Order Quantity (MOQ): We accommodate both small and large orders without minimum requirements.

6.Extensive Experience: With over 19 years in high-frequency PCB manufacturing, we bring expertise to your projects.

7.Production Capabilities: Our workshop spans 16,000㎡, with a monthly output capability of 30,000㎡ and the ability to produce 8,000 different PCB types monthly.

8.Support for R&D: Our robust PCB capabilities enhance your research and development, sales, and marketing efforts.

Applications

RF Transceiver

Power Divider

LNB Attenuator

Directional Coupler

Photocoupler

Parameter and Data Sheet

PCB SIZE |

140 x 35 mm=1PCS |

BOARD TYPE |

Multilayer PCB |

Number of Layers |

4 layers |

Surface Mount Components |

YES |

Through Hole Components |

YES |

LAYER STACKUP |

copper ------- 35um TOP layer |

RO4003C 0.203mm |

|

copper ------- 35um(1oz) MidLayer 1 |

|

FR-4 0.5mm |

|

copper ------- 35um(1oz) MidLayer 2 |

|

FR-4 0.2mm |

|

copper ------- 35um BOT layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

7.8 mil / 4.4 mil |

Minimum / Maximum Holes: |

0.3 mm / 2.5 mm |

Number of Different Holes: |

4 |

Number of Drill Holes: |

91 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

Rogers RO4003C +FR4 hybrid material |

Final foil external: |

1 oz |

Final foil internal: |

1 oz |

Final height of PCB: |

1.1 mm ±0.11 |

PLATING AND COATING |

|

Surface Finish |

Immersion silver |

Solder Mask Apply To: |

TOP and Bottom, 12micron Minimum |

Solder Mask Color: |

Blue, KSM-6189BL04/KSM-19H01 |

Solder Mask Type: |

LPSM |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

NO |

Colour of Component Legend |

NO |

Manufacturer Name or Logo: |

NO |

VIA |

Plated through hole(PTH), minimum size 0.3mm. |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |